The next generation of delta centrifugal corporation systems emphasizes automation, safety, and sustainability. Producers are adding AI-fueled monitoring to predict maintenance needs before mechanical issues arise. Improved rotor dynamics minimize vibration and energy consumption, and closed chambers prevent contamination at high speeds. Touch operation and multilingual interfaces simplify ease of use. In processing biological samples or industrial fluids, the new delta centrifugal corporation unites mechanical robustness with digital intelligence, setting the bar higher for precision, productivity, and durability in industrial and scientific applications.

The utilitarian uses of delta centrifugal corporation have expanded due to technological advancements. It is utilized in pharmacology to ensure high-purity drug formulations. It is utilized in biotechnology for protein crystallization and vaccine synthesis. The extractive industry utilizes delta centrifugal corporation to separate valuable minerals from raw mixture. In classrooms, it facilitates laboratory demonstrations of fluid flow. Even in the restoration of paintings, expert delta centrifugal corporation facilitate cleaning and stabilizing delicate pigments. The applicability of delta centrifugal corporation to so many different fields is evidence of its utility as an industrial and scientific agent for material separation.

Sustainability, connectivity, and accuracy will be the areas of future evolution of delta centrifugal corporation. Instruments will be made with sustainable materials and energy-efficient drives to minimize their carbon footprint. Real-time monitoring of data through cloud-based systems will facilitate real-time troubleshooting and process optimization. Portable versions will enhance accessibility in remote- or field-based studies. In pharma and biotech, delta centrifugal corporation will ramp up production with intelligent automation. As technology continues to evolve, delta centrifugal corporation will remain at the center of scientific innovation, bridging the gap between mechanical performance and digital intelligence.

Continuous cleaning and routine checkup maintain a delta centrifugal corporation in good working order. The rotor must be carefully inspected for distortion or corrosion because even small flaws can result in unbalance. Users should clean the interior chamber with a soft cloth at the end of each run to remove residues. Electrical and mechanical components must undergo regular checks for proper alignment and accuracy of speed. Periodic calibration at specified intervals maintains measurement precision. By implementing a formal maintenance regime and strict compliance with manufacturer instructions, the delta centrifugal corporation is dependable upon repetitive application.

Used in many applications, a delta centrifugal corporation uses rotational motion to facilitate material separation. Working through centrifugal force, it accelerates sedimentation, allowing scientists to sort particles based on density. Used extensively in laboratories, production plants, and environmental testing, the delta centrifugal corporation simplifies processes that would otherwise be tedious. Flexible, it can be used in anything from clinical diagnostics to food and drinks. With continuing improvement in rotor design and balance technology, delta centrifugal corporation today offer improved stability, endurance, and accuracy of data than before.

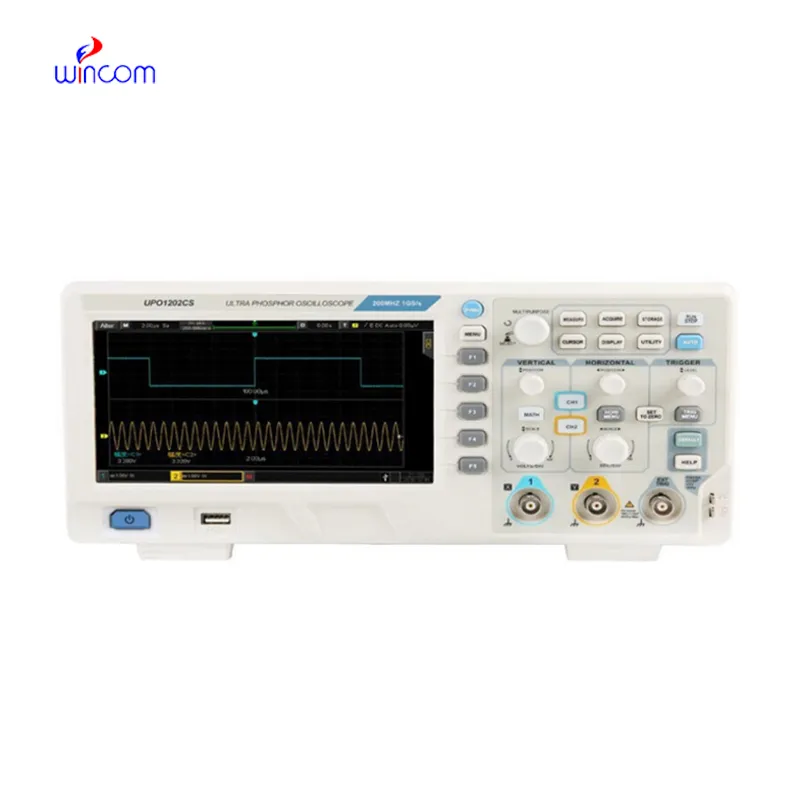

Q: What is a centrifuge used for? A: A centrifuge is used to separate mixtures based on density differences by spinning them at high speeds, allowing heavier particles to settle away from lighter ones. Q: How does a centrifuge work? A: A centrifuge operates by generating centrifugal force, pushing denser materials outward while lighter components remain near the center, resulting in effective separation. Q: What are common applications of a centrifuge? A: Centrifuges are used in laboratories, hospitals, and industries for blood testing, chemical analysis, purification, and sample preparation. Q: How often should a centrifuge be calibrated? A: Calibration should be performed at least once a year or whenever performance inconsistencies appear to ensure accuracy and reliability. Q: Can a centrifuge handle biological samples? A: Yes, many centrifuges are designed for biological materials such as blood, plasma, and cell cultures under controlled and sterile conditions.

The microscope delivers incredibly sharp images and precise focusing. It’s perfect for both professional lab work and educational use.

The centrifuge operates quietly and efficiently. It’s compact but surprisingly powerful, making it perfect for daily lab use.

To protect the privacy of our buyers, only public service email domains like Gmail, Yahoo, and MSN will be displayed. Additionally, only a limited portion of the inquiry content will be shown.

We’re currently sourcing an ultrasound scanner for hospital use. Please send product specification...

Could you share the specifications and price for your hospital bed models? We’re looking for adjus...

E-mail: [email protected]

Tel: +86-731-84176622

+86-731-84136655

Address: Rm.1507,Xinsancheng Plaza. No.58, Renmin Road(E),Changsha,Hunan,China