Crafted specifically for precision, the glass centrifuge tubes is additionally improved by digital and mechanical enhancements. Intelligent balancing systems automatically eliminate unbalanced loads, improving performance as well as safety. Materials such as reinforced polymers and high-grade aluminum are becoming standard in rotor production, reducing wear and maximizing life in operation. Real-time sensors of temperature and speed offer feedback for reliable results. These developments not only improve separation efficiency but also allow for the achievement of stringent laboratory standards. With increasing research needs, glass centrifuge tubes technology develops further to ensure better reliability and reproducibility.

Clinical laboratory environments utilize glass centrifuge tubes as an important tool for proper diagnosis. Blood banks utilize it to efficiently isolate red cells, plasma, and platelets. Research laboratories employ glass centrifuge tubes to examine tissue samples for cellular and molecular studies. In the energy industry, it assists in the manufacture of biofuels by isolating the biomass components. Food scientists employ glass centrifuge tubes to reclaim fats and purify proteins while preparing products. The numerous applications reflect its capacity to enhance data reliability, process control, and yield output in a wide variety of industries and research applications.

glass centrifuge tubes will integrate digital intelligence and cutting-edge engineering in the years to come. Complex algorithms will auto-tune parameters for optimum efficiency and safety. Energy-optimized designs will keep operating costs at a minimum and help support global green efforts. Robotics integration will facilitate round-the-clock unattended operation in big production setups. Modular design will provide ease of customization, allowing users to set up glass centrifuge tubes for specific scientific or industrial uses. These improvements will allow glass centrifuge tubes to not only increase performance but also establish new standards for automation, accuracy, and sustainability in the lab environments of the future.

For long-term efficiency, glass centrifuge tubes must be maintained with thorough attention to detail of operation. Every rotor and adapter must be checked for integrity before sample loading. After every cycle, the apparatus needs to be washed with neutral detergents and dried thoroughly. Vibration and mechanical stress are prevented by regular tests of balance. Seals and filters need to be replaced according to service schedules. Dust deposition is prevented by keeping the instrument in a covering when not used. If glass centrifuge tubes apparatus is cared for according to disciplined procedure, equipment will give consistent high-performance performance year in year out.

Used in many applications, a glass centrifuge tubes uses rotational motion to facilitate material separation. Working through centrifugal force, it accelerates sedimentation, allowing scientists to sort particles based on density. Used extensively in laboratories, production plants, and environmental testing, the glass centrifuge tubes simplifies processes that would otherwise be tedious. Flexible, it can be used in anything from clinical diagnostics to food and drinks. With continuing improvement in rotor design and balance technology, glass centrifuge tubes today offer improved stability, endurance, and accuracy of data than before.

Q: How is a centrifuge different from a mixer or shaker? A: Unlike mixers or shakers that blend materials, a centrifuge separates components based on density through high-speed rotation. Q: What power requirements does a centrifuge need? A: Most benchtop centrifuges use standard AC power, while industrial units may require higher voltage for greater speed and capacity. Q: Can a centrifuge be used in pharmaceutical production? A: Yes, centrifuge equipment is widely used to purify chemical compounds and biological materials during drug manufacturing processes. Q: How do I prevent vibration during operation? A: Ensure all tubes are evenly loaded, rotors are clean, and the machine is placed on a stable, level surface. Q: What is the lifespan of a centrifuge? A: With regular maintenance and proper usage, a centrifuge can last for many years while maintaining consistent performance.

The microscope delivers incredibly sharp images and precise focusing. It’s perfect for both professional lab work and educational use.

The water bath performs consistently and maintains a stable temperature even during long experiments. It’s reliable and easy to operate.

To protect the privacy of our buyers, only public service email domains like Gmail, Yahoo, and MSN will be displayed. Additionally, only a limited portion of the inquiry content will be shown.

Could you share the specifications and price for your hospital bed models? We’re looking for adjus...

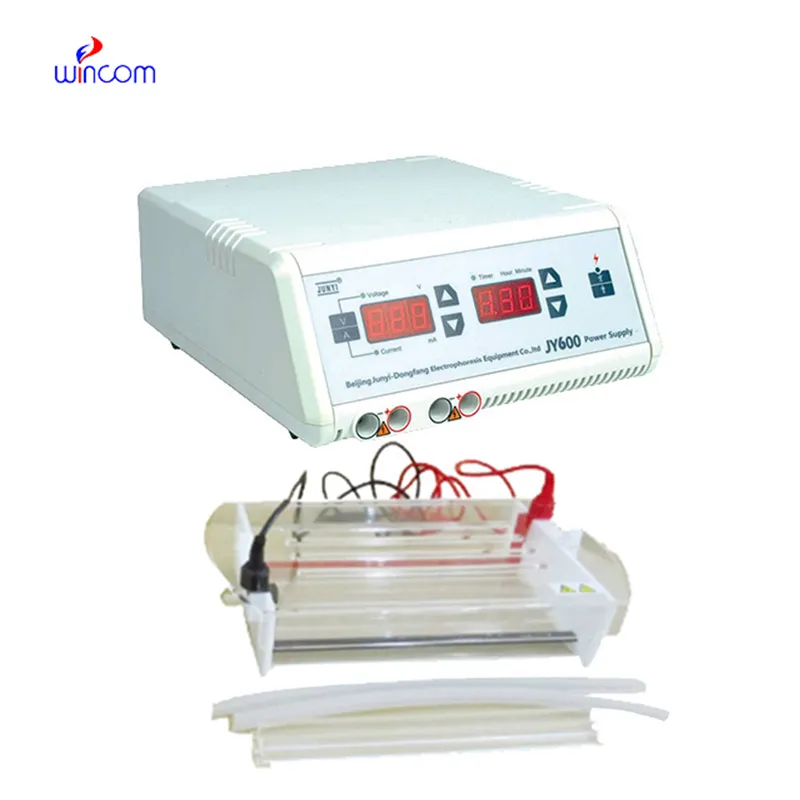

We’re looking for a reliable centrifuge for clinical testing. Can you share the technical specific...

E-mail: [email protected]

Tel: +86-731-84176622

+86-731-84136655

Address: Rm.1507,Xinsancheng Plaza. No.58, Renmin Road(E),Changsha,Hunan,China